Quality starts with experience

VELCO GmbH is a medium-sized company based in Velbert, located in the Düsseldorf-Essen-Wuppertal city triangle. For 50 years, quality and competence have been our top priorities when it comes to the processing of gunning mixes, low-wear pneumatic conveying and the injection of bulk materials into processes of all kinds. More than 1000 satisfied customers worldwide in the steelworks, foundries, refractory and construction industries speak for themselves.

Your partner for demanding construction projects

VELCO produces high-quality concrete gunning machines for the construction and refractory industries. We support you with our concrete spraying technology for your projects and supply you with our quality products.

Concrete spraying in the construction industry

Shotcrete is mainly used in the construction industry. Applications include the reinforcement of concrete structures, lining of tunnels and galleries as well as bridge renovation and design work in gardening and landscaping. The state of the art is the processing of factory-mixed dry construction materials, where a distinction is made between sprayed mortar and sprayed concrete. In recent years, VELCO has developed the patented GUNMIX® system, which improves wetting during spraying and reduces dust generation and rebound. Particularly in tunnel construction and in many other areas, low-dust dry spraying is essential due to the stringent requirements of the environmental protection authorities. In addition, the strain on the operating personnel is lower. With VELCO spraying machines, both traditional shotcrete and dry construction materials can be processed using the spraying method.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

REFRACTORY TECHNOLOGY

Refractory materials are used when metal melts are generated or extreme heat develops through combustion processes. They offer optimal protection for people and equipment. The refractoriness is created by various ceramic and inorganic components, which is why a high processing quality is essential. For dry-spray processing, you need pulsation-free conveyance of the spraying compound and good, uniform moistening. We supply rotor and pressure vessel spraying machines for this purpose.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Would you like individual advice on our machines?

GUNMIX®: AN INNOVATION BY VELCO GMBH

The new GUNMIX® process is an efficient further development of the proven dry spraying process. Here, the sprayed material is moistened in the mixing head with the help of compressed air-water mist and the dust formation as well as the rebound are considerably reduced. The amount of water added and the spraying rate can be precisely adjusted and measured. This allows the mixing ratio of spray material and water to be maintained. This results in new fields of application and conventional techniques are facilitated.

The GUNMIX® system can be combined with rotor or pressure chamber sprayers. In addition, retrofitting of older VELCO spraying machines is also possible. The machines are used in the construction industry and in the refractory industry. They are available in two versions: the GUNMIX® humidification system in the basic version and the GUNMIX®-humidification system mobile.

The GUNMIX® system convinces with the following advantages:

- Better working conditions due to less dust formation

- Better spraying results due to optimal humidification

- Cost saving due to reduced rebound

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

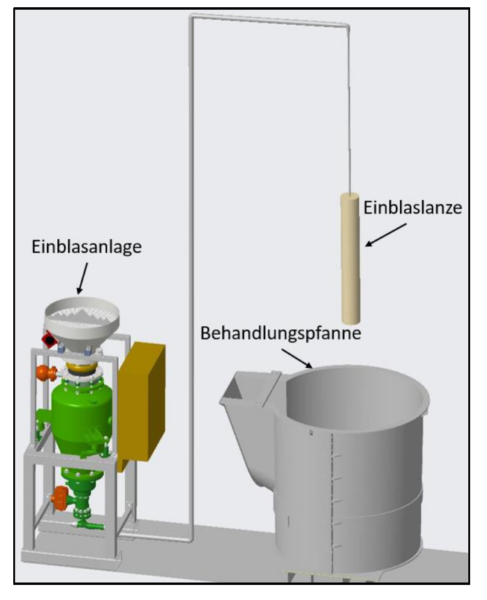

Injection systems for pneumatic conveying

In the pneumatic conveying of bulk materials, a distinction is made between thin-flow, mixed-flow and dense-flow conveying. Dense-phase conveying has the advantage of a high material load and a resulting low material speed. This reduces the wear of the conveying line and also the maintenance and operating costs. VELCO machines can be used to convey various bulk materials such as coal dust, lime, additives, DRI and filter dust.

Successful projects with concrete spraying technology from VELCO

With our long-standing experience, we have been reliably supplying our customers with pneumatic conveying systems, silo systems and concrete spraying machines since 1971. We are also happy to support your projects in the construction, refractory, foundry or steel industry. Rely on innovative solutions from VELCO GmbH in the future and let us advise you without obligation. Send an e-mail to info@velco.de or contact us via our contact form.