Pressure vessel gunning machines

The use of pressure vessel gunning machines is recommended, when bigger amounts of gunning material shall be processed.

These machines cause only very low wear costs due to their construction principle. In most cases the machines are filled BIG BAGs, but it is also possible to use a pre-container for the storage of gunning material. The machine can be supplied either supplied as mobile version equipped with wheels or as stationary model for transportation by fork lift or crane.

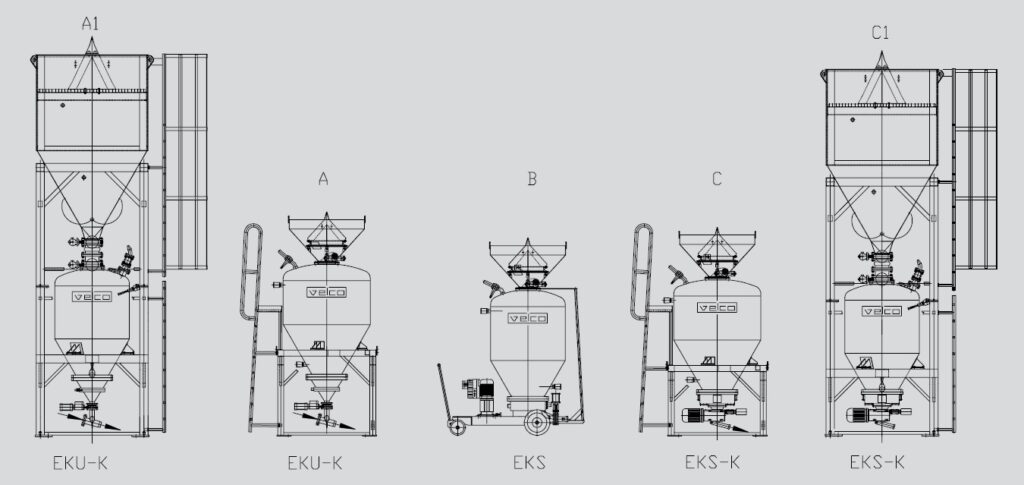

EKS

A pressure vessel gunning machine type EKS is more economic, when bigger amounts of refractory material shall be processed for instance for the repair of EAF, converters or ladles.

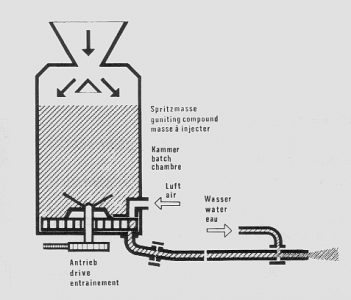

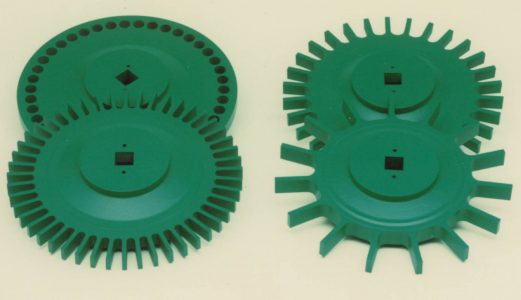

The machine type EKS is mobile, equipped with an integrated dosing system (flow impellers made of grey cast iron or steel cast) and can be used for gunning capacities from 0,5 – 6,0 m³/h.

Change of gunning capacity is possible via motor speed or chamber pressure. The vessel volume can vary from 0,5 – 3 m³. Machine filling can be done by sacks or BIG BAGs. A bell-shaped valve is used as closure device.

EKS-K

The EKS-K is the stationary version of machine type EKS with comparable technical data.

It is equipped for transportation by crane and fork lift, machine filling can be effected by sacks, BIG BAGs or silo/bunker.

The machine can be provided with several outlets (Twin/Triple). This allows for instance to serve two furnaces by one machine to gun them independently from each other without changing the coupling of hose connections.

Machine control can be done via remote control.

EKU

The deliberate simple and user friendly pressure vessel gunning machine EKU has been designed for the hot repair of converters, electric arc furnaces and ladles.

The gunning material is discharged pure pneumatically and dosed. The machine can be filled by sacks or BIG BAGs.

A bell-shaped valve is used as closure device. Gunning capacity 1,0 – 5,0 m³/h. The vessel volume can vary from 0,5 – 4 m³.

Would you like individual advice on our concrete gunning machines?