CONCRETE GUNNING MACHINE FOR THE CONSTRUCTION INDUSTRY

Gunning concrete is used in the construction industry already for many years. Typical applications are the reinforcement of concrete structures, the lining of tunnels and galleries, bridge renovations, but also design work in gardening and landscaping. The dry gunite process is often used here. From Velco GmbH you get high quality concrete gunning machines for the construction industry. We support you in your construction projects with our quality products.

Advantages of our concrete gunning technique

Compared to the wet gunning process, the machine technology is more handy, easier to clean and better suited for smaller jobs such as concrete renovation. The state of the art is the processing of factory-mixed dry construction materials (DIN 18551). A distinction is made between gunning mortar and gunning concrete. Depending on the task, for example microsilica, bonding accelerators or polymer modified compounds (SPCC) are added. For high-quality repairs, uniform delivery of the gunite compound and homogeneous moistening are necessary. Thanks to the GUNMIX® moistening system developed and patented by Velco, the humidification during the gunite process is improved and the development of dust and rebound are significantly reduced.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Rotor GUNNING MACHINES

The rotor gunning machines are continuously operating devices that are characterized by their large performance range. They are also common in the refractory industry. From Velco you get the concrete gunite machines Rotamat tb, RON and NA. They can be equipped with additional accessories as required.

The Rotamat tb is a gunning machine based on the rotor principle. It is suitable for a simple processing of all listed dry building materials in concrete renovation and has already proven itself successfully on many construction sites. Especially in combination with our patented GUNMIX® system, you get an efficient gunite machine for gunning repairs on concrete structures.

The machine has been tested and approved in accordance with ZTV-SIB 90. It is an ideal solution especially for processing SPCC mortar: Depending on the equipment of the machine, performance ranges between 0,25 and 4,0 m3 / h can be achieved. Thanks to our more than 50 years of experience in gunning and torcreting technology, with the Rotamat tb you get a gunite machine that impresses with its efficiency and economy.

Our Rotamat type tb gunning machine with the appropriate equipment has been specially tested and approved for the renovation of concrete structures with listed SPCC materials.

An overview of the equipment of the Rotamat tb gunning machine with Gunmix® moistening system:

- Electric drive with frequency inverter (low maintenance)

- Ball vibrator at the filling hopper and compressed air gun for cleaning the machine

- GUNMIX® humidification system (European patent number: 1153861)

- Cable remote control with automatic start / stop sequence

- Complete mobility via chassis, crane hooks and forklift receipts

- Boost pump for water (max. 14 bar)

- Compressed air filter with automatic water separator

- Protection cover with transparent curtain

The following accessories are available as optionally:

- Full housing of the motor, switch cabinet, water pump and valve station

- Digital water flow meter

- Radio remote control instead of the cable remote control

- Transport pallet

Gunning machine NA

Gunning machine RON

For the processing of gunning material with a higher humidity share, so-called plastic materials, Velco has the gunning machine NA and RON in their production program.

Gunning machine NA

This is a continuously conveying machine based on the rotor system. It can convey and process both pre-moistened (so-called plastic) gunning mixes with a moisture content of six to eight percent as well as dry materials. Via a sieving hopper, the material to be processed is fed into the staggered pocket wheel. From there it is finally transported through a hose- or pipe line to the place of use, using the thin-stream method with compressed air at 0,5 to 6 bar. Easily exchangeable friction wheels at the rotor ensure that wear costs are kept as low as possible. In addition, two rubber segment sealing disks, which are common with the rotor system, also contribute.

The NA concrete gunite machine is available in several sizes and different performance levels. In addition, the device can be supplied with additional accessories on request. This includes, for example, a water pump, a remote control, a vibrating sieve and additional moistening.

Gunning machine RON

The additional equipment RON works in a lower capacity range than the type NA. The equipment can be installed on all Velco Rotamat gunning machines and converts dry gunning- into wet gunning machines.

The technical data at a glance

- Gunning capacity depending on the machine type and gunning material between 1.0 and 2m³ / h RON or 4.5 and 9m³ / h (NA)

- Distribution wheel, agitator and blow-out socket especially developed for gunning mixes with high humidity

- Electric motor drive

- Version with wheels or alternatively with receipts for transport with forklifts

Accessories for the rotor gunning machines & application

- BIG BAG filling device

- Various gunning equipment for concrete gunning

- Radio remote control

- Cable remote

- Control cabinet

- Pressure increase pump

Transport unit for VELCO – Rotamat

This transport unit for the VELCO rotor gunning machines enables a safe displacement of the machine by means of forklift, crane or truck inside or even outside the plant. The transport unit distinguishes by simple and safe handling. The Rotamat machine is set on the transport unit, easily fixed and soon ready for transport. The unit is furthermore equipped with a lockable box where the gunning equipment, friction wheels, packing washers and tools can be orderly and safely kept with the machine.

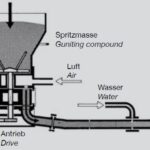

GUNMIX®: AN INNOVATION FROM VELCO

The GUNMIX® process is an efficient further development of the previously proven dry gunning process. In this way, you achieve less dust nuisance, less rebound and more intensive mixing. The gunning material is moistened in the mixing head by means of a compressed air-water mist, which serves to reduce dust and rebound. The GUNMIX® moistening system can be combined with rotor or pressure vessel gunite machines.

Advantages of the GUNMIX® moistening system in the construction industry:

- Dry construction materials do not have to be pre-moistened and can be applied with little dust and less rebound

- Conventional gunning concrete is applied even more economically, as more intensive moistening is guaranteed

- Better working conditions due to less dust emission

- Cost savings due to less rebound

- Better gunning results thanks to optimized moistening

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Successful projects with VELCO concrete gunning technology

We have been reliably supplying our customers with dry gunning machines and pneumatic conveying systems since 1971. We would also be glad to support your projects in the construction, cement, refractory, foundry or steel industries. Rely on innovative and economical solutions from Velco GmbH in the future and let us advise you without obligation. Send an email to info@velco.de or contact us using our form.

Would you like individual advice on our concrete gunning machines?