GUNMIX® - the Revolution of dry gunning

The so far established dry gunning process has got an efficient improvement by this new process as for instance less dust nuisance and rebound and more intensive mixing.

At the GUNMIX® moistening system (EP 1153861), the gunning material is moistened by a mist of compressed-air and water.

The use of this system reduces considerably dust development and rebound. The addition of water is exactly adjusted and can be metered. By use of a gear motor with speed control the gunning capacity is exactly adjusted, too.

This allows to keep an exact mixing ratio of gunning material and water.

New fields of application arise when LCC-, ULC- or NCC-materials are applied in the dry gunning. Due to the better moistening with GUNMIX® these materials can be processed with dry gunning machine while adding little binding agent (water glass, acid or water).

Compared with the conventional casting application the extensive formwork is not applicable.

Moreover, the use of GUNMIX® is a cost-saving alternative to extensive procedures like shotcreting, since it is worked with a simple machine technology and there is less loss of material during adjustment and cleaning of the machine.

The GUNMIX® moistening system can be combined either with rotor or pressure vessel gunning machines. Even the upgrade of older Velco gunning machine is possible.

without GUNMIX ® - atomizer air

with GUNMIX ® - atomizer air

Areas of application of GUNMIX®

Construction industry

- Dry building materials must no longer be pre-moistened and can be applied nearly dust-free and with less rebound

- Conventional gunning concrete is applied even more economical, since a more intensive moistening is guaranteed, at an exact low water-/cement factor.

Refractory industry

- Particularly helpful in closed and tight spaces as for instance shaft furnaces (cupola furnaces), cyclones in the cement industry, vessels of incineration plants, since the dust development is considerably reduced at the dry gunning.

- Hot repairs with high-alumina materials, for instance for the gunning repair of steel plant ladles at porous plug and well-block

- Low-cement gunning materials (LC, ULC, NC) can be processed in the dry gunning technique with only low rebound. Approx. 30% less rebound compared with conventional high-pressure water systems.

GUNMIX® in action

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

GUNMIX® Moistening system

The solution for existing gunning machines

The basic as well as the mobile GUNMIX® moistening system have been developed to equip an existing gunning machine with the GUNMIX® gunning technology.

This kind of gunning technology improves the approved dry gunning process, makes it more efficient, reduces dust emission and rebound and enables a more intensive mixing of material and water.

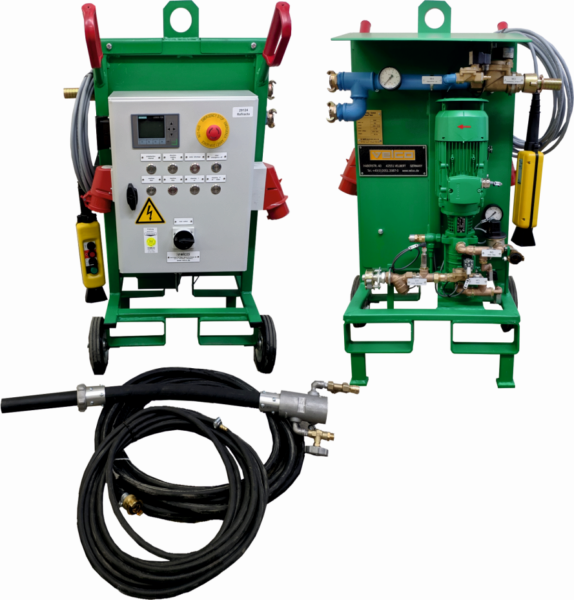

GUNMIX® moistening system - mobile execution

- pressure increasing pump 14 bar, 12 l/min

- remote control automatic for the reliable control of gunning air and water

- connected outlet 4 kW for the motor of a rotor gunning machine

- upport frame with rolls and attachment for crane and forklift

- optionally: electr. water flow meter

GUNMIX® moistening system - basic version

- pressure increasing pump with bypass 14 bar, 12 l/min

- direct switch-on at the motor protection switch

- mobile frame

- optionally: rotamater

Gunning machine with GUNMIX®-Equipment

Advantages by using the GUNMIX®-system:

- better working conditions due to less dust development

- better gunning result due to better moistening and non-arising of nests

- savings of costs due to less rebound

Application

Results

Would you like individual advice on GUNMIX®?