Application in the foundry industry

Metal casting has been a method that has been tried and tested for thousands of years to produce castings in small and large numbers at low cost. Traditional cast materials are gray cast iron and cast steel. Cupola furnaces (shaft furnaces), rotary kilns, electric arc furnaces or induction furnaces are used for melting.

With Velco gunite machines you can carry out refractory repairs on all furnaces. With our pneumatic conveyor systems, you can blow bulk goods such as coal dust, filter dust or silicon carriers into the cupola and thus save operating costs. By adding alloys automatically to the ladle, you can improve your casting quality. Even with small melt sizes of 5-10t, the deep injection of fine lime can reduce the sulfur content at low cost.

Application examples

Gunning repair of the cupola using a hydraulic lifting platform

The daily gunite repair of the small cupola shaft is a strenuous and dangerous job. Improve the working conditions by using a hydraulic lifting platform. The appliance is moved under the cupola with the bottom flap open and the worker can control the extension of the hydraulic cylinder via buttons and reach different zones for guniting.

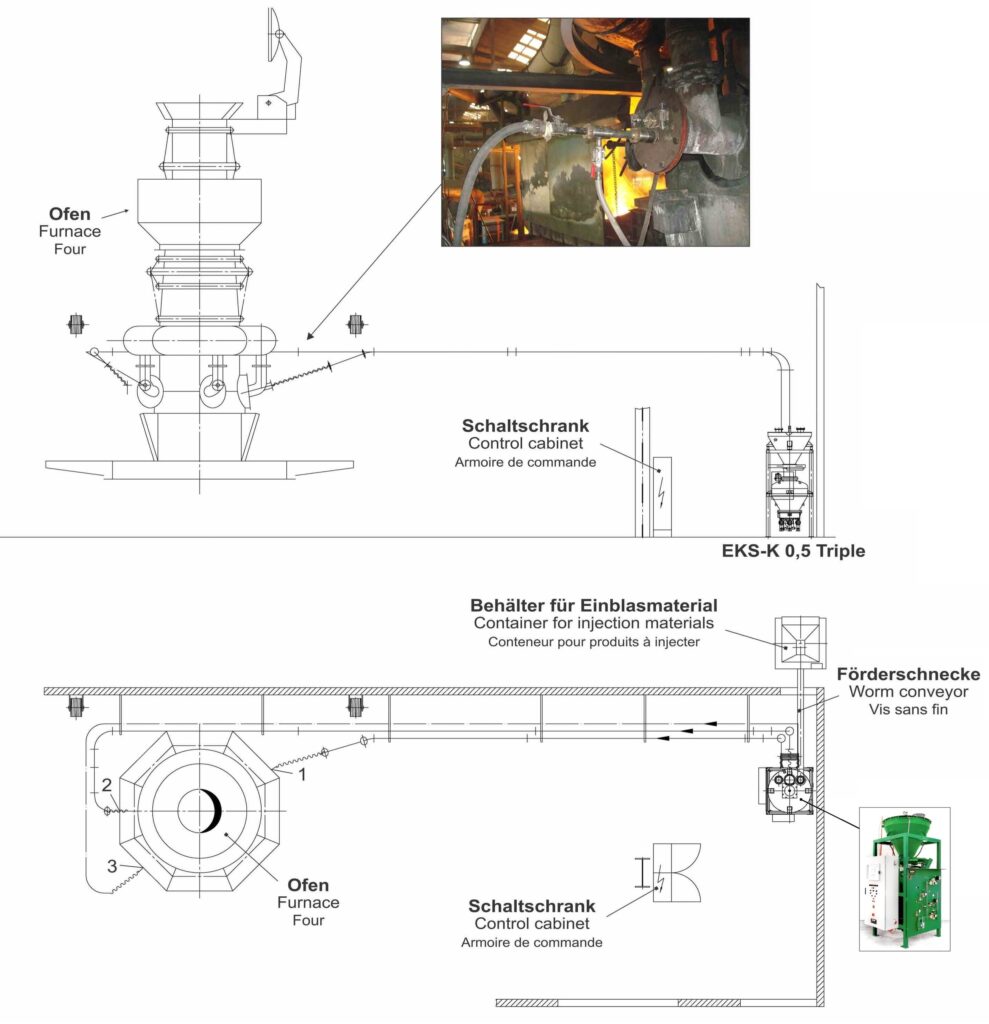

Zinc and Iron Recovery from Filter Dust by Melt Bath Injection into an Induction Furnace

The increased proportion of galvanized materials in circular scrap leads to an increased zinc-content in the filter dusts of iron and steel plants.

The recovery of this raw material from a waste material is not only interesting from an environmental point of view but also from the economic one.

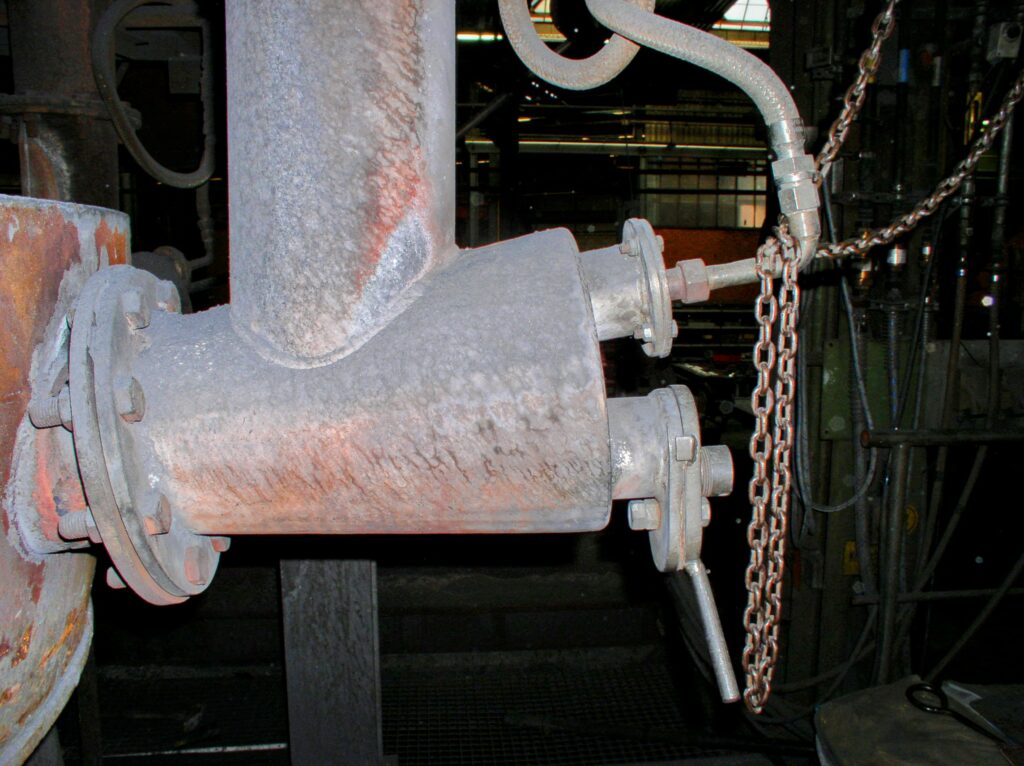

As part of a BMBF research project, VELCO has blown Zn-containing filter dust into a molten metal for a customer, whereby a highly concentrated zinc oxide product is produced.