rotor gunning machines

The rotor gunning machines are continuously operating devices that are characterized by their large performance range. They are also common in the refractory industry. From Velco you get the concrete gunite machines Rotamat f, RON and NA. They can be equipped with additional accessories as required.

Rotamat f

The Rotamat f is a gunning machine based on the rotor principle. This is ideal for processing refractory concrete using the dry gunning method and has already proven itself successfully in the construction industry. Especially in combination with our patented GUNMIX® system, you get an efficient gunite machine for gunning repairs on concrete structures.

Especially in combination with our patented GUNMIX® system, you get an efficiently working gunning machine as well as for hot repair and bringing in refractory concrete in a cold state.

An overview of the equipment of the Rotamat f gunning machine with Gunmix® moistening system:

- Electric drive with frequency inverter (low maintenance)

- Ball vibrator at the filling hopper and compressed air gun for cleaning the machine

- GUNMIX® humidification system (European patent number: 1153861)

- Cable remote control with automatic start / stop sequence

- Complete mobility via chassis, crane hooks and forklift receipts

- Boost pump for water (max. 14 bar)

- Compressed air filter with automatic water separator

- Protection cover with transparent curtain

The following accessories are available as optionally:

- Full housing of the motor, switch cabinet, water pump and valve station

- Digital water flow meter

- Radio remote control instead of the cable remote control

- Transport pallet

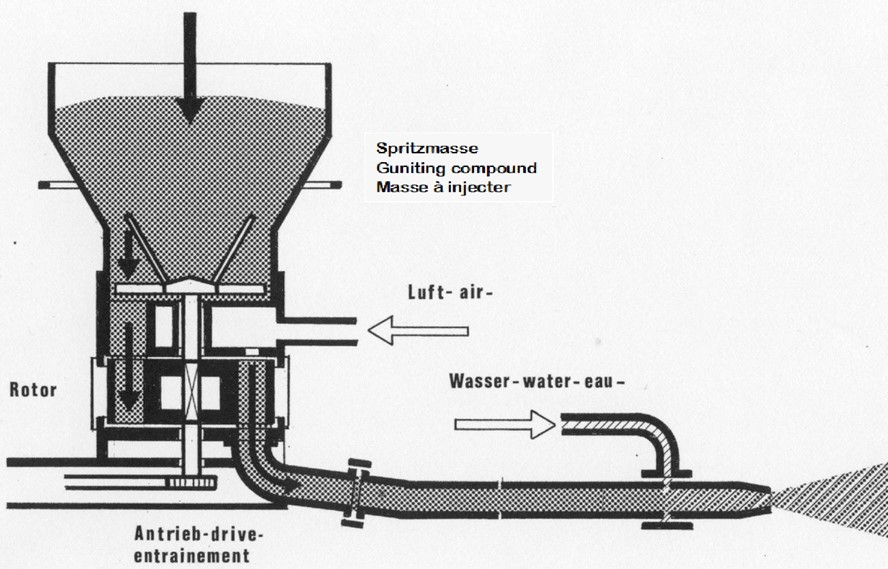

Principle of rotor gunning

The guniting compound is placed into the hopper by sacks. Then the material falls through the hopper and the upper part of the machine into a rotor chamber. The standard rotor has 9 rotor chambers. The gunning capacity is changed by the size of the rotor chambers and the speed of the rotor. The gear motor drives the rotor via a robust chain. The filled rotor chamber rotates from the filling to the emptying position. There the gunning material is blown into the hose by using compressed air and then moistened with water. This creates a pasty mass that sticks to a wall or ceiling.

At dry gunning, a low level of dust development at the machine and the spraying nozzle is important. The Rotamat therefore has a four-point clamping for evenly pressing the friction wheel and the sealing discs.

Depending on the equipment of the machine, performance ranges between 0.25 and 4.0 m3/h can be realized. Thanks to our more than 50 years of experience in gunning and torkreting technology, with the Rotamat f you get a spraying machine that impresses with its efficiency and economy. Our customers use the machine to process both insulating concrete, acid gunning mixes, basic (magnesite – basis) and high-alumina (alumina – basis) materials.

Different water rings, spraying nozzles or lances are available to achieve the best possible result for the various applications.

Would you like individual advice on our concrete gunning machines?