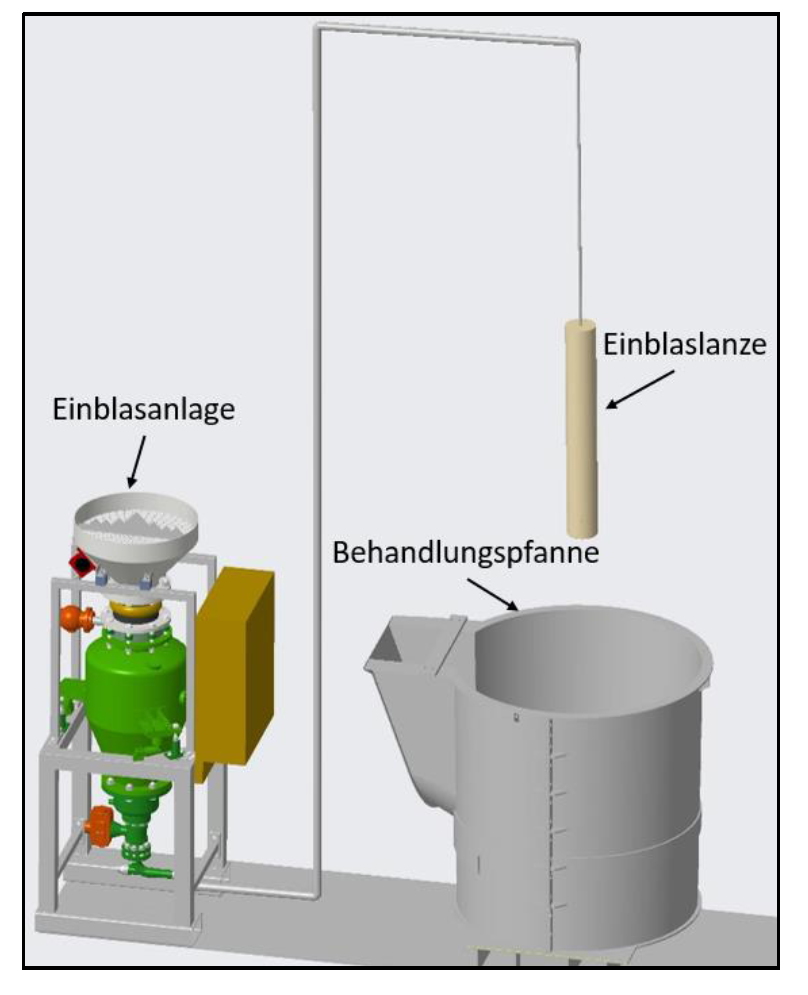

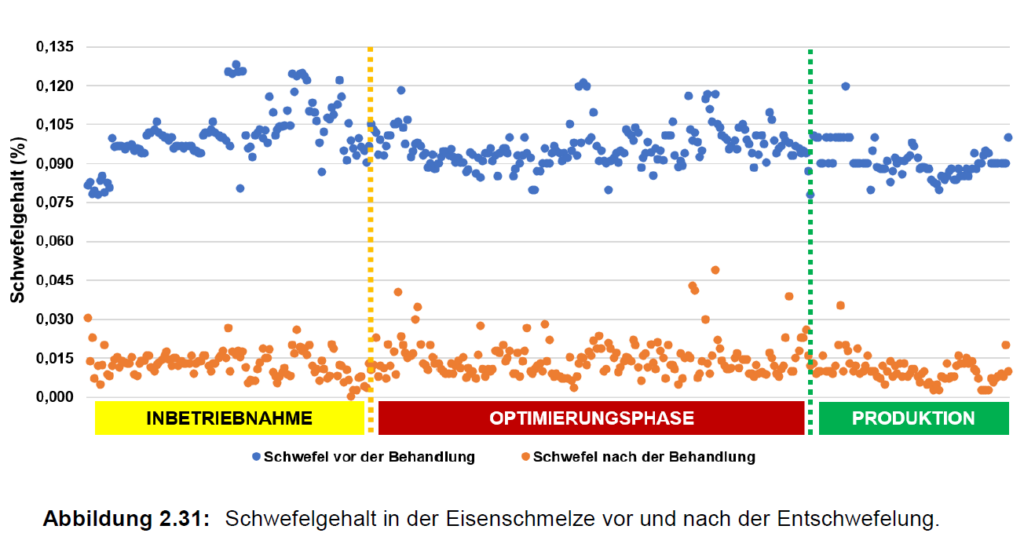

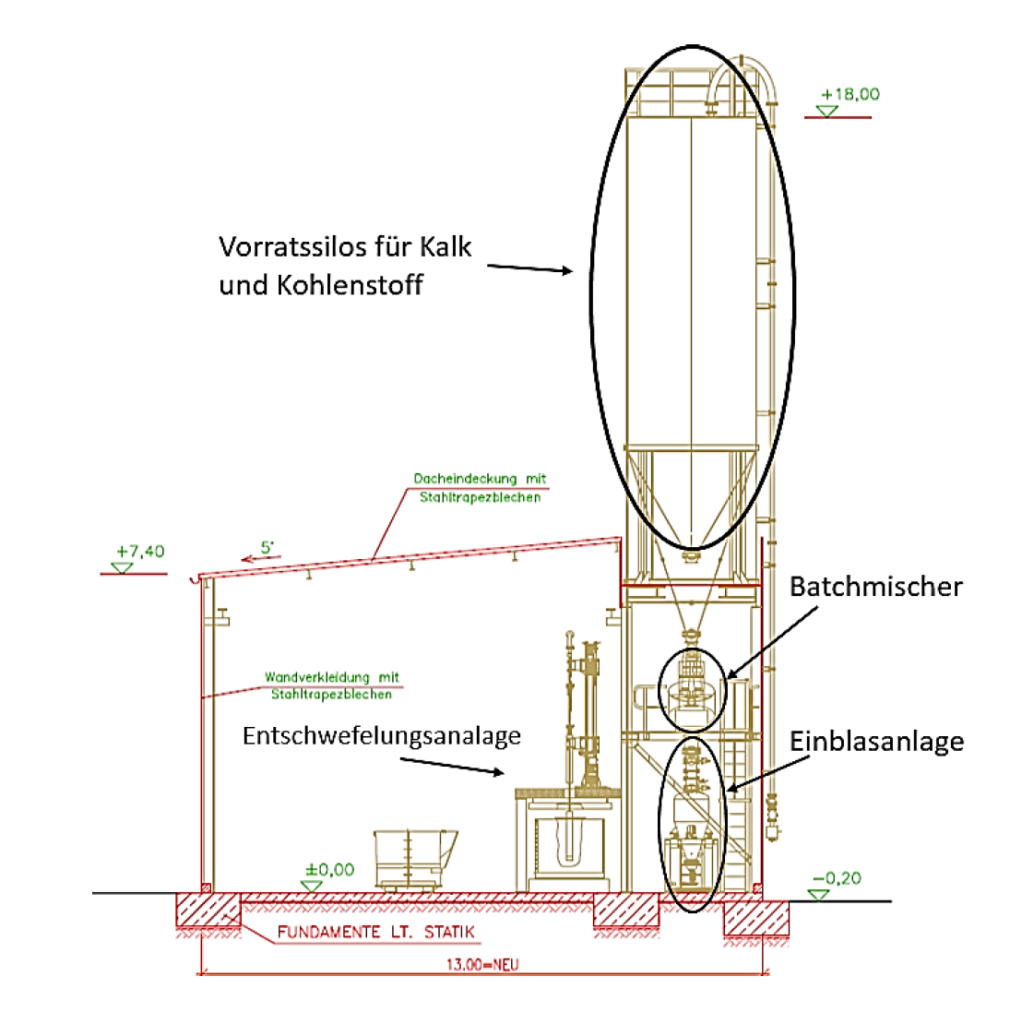

Fritz Winter Eisengießerei GmbH und Co. KG in Stadtallendorf has commissioned an innovative plant for lime-based desulfurization of cast iron melts. The plant was supplied by VELCO GmbH located in Velbert/Germany. A mixture of fine lime and coal is pneumatically injected into a ladle containing approx. 2.5t of cast iron. This reduces the sulphur content in the melt from approx. 0.1% to below 0.015%. The installation consists of a silo for lime, a silo for coal, a batch mixer, a screening machine, the pneumatic transmitter and a lance manipulator for a ceramic immersion lance. The treatment takes about 6 -8 mins, during which a mixture of fine lime and coal is injected into the melt. By adding coal, it is possible to selectively adjust the carbon content of the melt in addition to desulfurization.

For the production of GJS and GJV grades, the cast iron must be desulfurized. Magnesium is generally used for this purpose and is fed into the melt in the form of FeSiMg wire. The turbulence on the international raw material markets has made the availability of Mg scarce and caused the price to rise dramatically.

With the support of the Institute for Technologies for Metals of the University of Duisburg Essen and the Institute for Building Materials Research e.V. of FEhS, Fritz Winter Eisengießerei GmbH und Co. KG has installed this novel desulfurization plant and developed a corresponding desulfurization process. The project was funded within the framework of the r+ Impulsvorhaben.

The scientific monitoring of the commissioning has proven that there is no reduction in the quality of the iron, but that there are major ecological and economic advantages. As lime is available regionally, operation of the new plant helps to decouple the company from the uncertainties of the raw material markets.